What Is Blow Molding?

Transforming heated plastic into functional form.

At its core, blow molding is the process of creating hollow plastic parts — like bottles, jars, jugs, and industrial containers — by inflating a molten polymer tube (parison) inside a mold. Rigid Sustainable Solutions works directly with extrusion blow molding (EBM), a method known for its versatility, speed, and ability to produce complex packaging forms, including multi-layer containers with integrated handles, angled necks, and more. By leveraging this technology, RSS is developing recyclable, high-performance rigid packaging that meets diverse industry needs and supports future-focused innovation.

Why It Matters to Us

High-performance sustainability at scale

Rigid packaging in the food and beverage industry demands more than just shape — it must withstand pressure, protect freshness, and extend shelf life. While many sustainable materials fall short in these areas, extrusion blow molding allows RSS to develop next-gen packaging that meets four core criteria for viable plastic alternatives: high performance, competitive pricing, scalable manufacturing, and clear end-of-life claims. With growing partnerships and an R&D lab presence at Miami University, we are building the groundwork for real-world applications that can rival — and replace — conventional plastics.

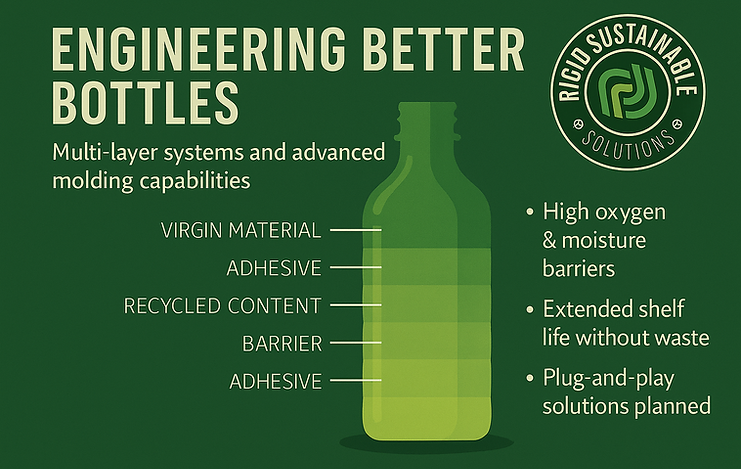

Engineering Better Bottles

Multi-layer systems and advanced molding capabilities

RSS is actively exploring multi-layer extrusion blow molding, a process where up to seven layers can be used to achieve high oxygen and moisture barriers. This enables extended product shelf life without relying on traditional plastic waste. We’re investigating combinations that may include virgin material layers, recycled (PCR) content, and adhesive bonding layers — along with barrier resins — to ensure performance in challenging conditions like refrigeration, heat, and light exposure. Future plans include the development of plug-and-play bottle solutions that require zero equipment changes for existing producers.

From Concept to Shelf

Where our design and sustainability goals align

Every blow-molded container RSS develops starts with one goal: making sustainability seamless. Working alongside partners and advisors, our focus is not only to engineer better packaging — but to do so while maintaining compliance, aesthetic value, and product integrity. This is packaging made with both the product and the planet in mind.

Looking Ahead

Blow molding as a launchpad for fiber alternatives

While much of our innovation today is built around blow-molded plastic packaging, the long-term vision at Rigid Sustainable Solutions is to use this knowledge to inform the future of plant-fiber-based rigid packaging. Our understanding of high-strength, shelf-stable design directly supports our fiber packaging research — enabling smarter hybrid solutions and a smoother transition away from plastic. With spray coatings, liners, and lamination tech already in play, we see blow molding as not just a manufacturing technique — but a foundation for what’s next in circular packaging.